VHMED is an end-to-end, integrated manufacturer for minimal invasive therapies. We are working closely with the leading surgeons in Asia and Europe to develop the ideas and concepts for modern healthcare. We attend laparoscopic procedures in various specialties, general surgery, colorectal, gynecology and urology to understand the clinician's needs.

PRODUCT DESIGN

A list of design tools we use:

3D Printing in Plastics & Metal

Computer Numerical Control

Rapid Prototyping

Rapid Tooling

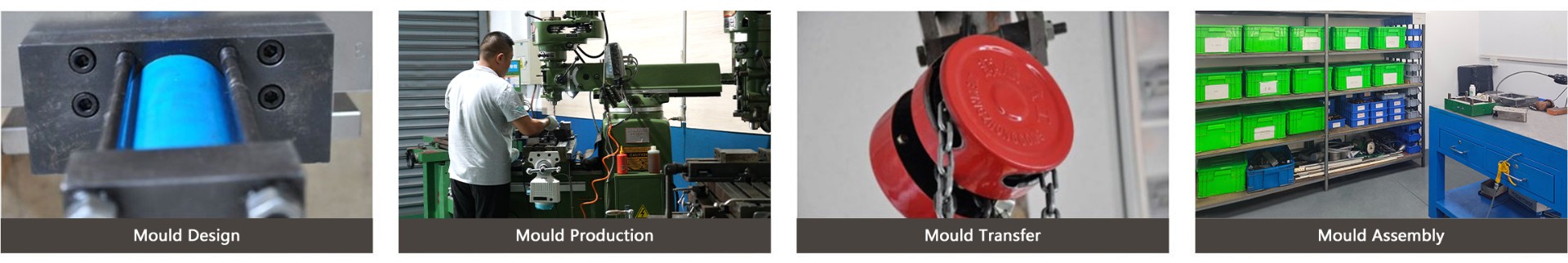

INHOUSE MOULD PRODUCTION

At VHMED, we design, produce the mould inhouse. The plastic components of the product design are translated into injection mould design. Our mould production team then produce the mould parts and components. Upon completion, all components are assembled together to produce injection moulding parts.

METALWORKS

At VHMED, we produce both plastic and metal components inhouse to the specified designs. The mechanical facilities and machineries include:

Lathe

Drilling

Milling

Punching

Electronic Line Cutting

Deburring

SUBASSEMBLY

Our subassembly line includes manual, automatic and semi-automatic assembly, include facilities:

Ultrasonic Welding

Laser Welding

Pad Transfer Printing

Manual and Automatic Glue Application

FINAL ASSEMBLY, PACKING AND STERILIZATIONS

Our final assembly line is located in a large scale ISO Class 7 cleanroom environment. It has a carefully layout design for a quick and high volume throughput. We are operating EtO sterilization in our own facility.